Logistics & Supply Chain: modern industry means modernized supply chains

Production line modernization efforts through automation, the use of cloud technologies, digital twins, and data management tools can bring impressive results throughout an organization’s supply chain.

The new possibilities of technological progress and the opening of additional logistical markets in the production area have created an environment where companies are able to invest in technological equipment and new types of software at quite affordable prices.

According to the American Association for Manufacturing Technology, 2019 was the United States’ best year since 1996 in terms of orders for new types of technology.

Also, in the current period, many of the capital investments that were previously considered unfeasible or potentially damaging to small and mid-sized industrial companies have now become considerably more affordable.

New technologies have also played a key role in the evolution of supply chains. Ongoing technological developments such as augmented reality, instant digital manufacturing and warehouse automation open up a new world of opportunities in the light of the supply chain.

These new technologies not only allow increasing the efficiency and flexibility of production and distribution processes, but also modify the relationship between the different stages of the supply chain, with a particular focus on the consumer.

For this reason, the use of these technologies has been seen as one of the key tools for businesses to enhance their competitiveness and build more stable relationships with supply chain links. Consequently, technological applications in supply chain management have become an area of research, given their clear and strong managerial impact.

In order to modernise its entire production line, an organisation must take into account all operational parameters, from the current supply chain to encouraging possible future investments. A holistic approach is therefore required, taking the right risks and constantly monitoring the upcoming changes.

A deep understanding of the new technologies that are capable of having a real impact on the production process of companies is a colossal challenge. As with past innovations, the applicability and potential impact of these technologies vary.

The multifactorial nature of new technologies makes it a difficult task for companies to identify the most appropriate area to focus their supply chain technology investments, while opening up the “appetite” for forcing real changes in the competitive game.

In contrast to industrial companies, 8 out of 10 3PL and 4PL companies are investing in warehouse software and fleet management systems, although 4th industrial revolution technologies remain limited.

In particular, warehouse management is mainly done with WMS systems (61% of companies), the use of fleet management systems is widespread (52%), while digital RFID sensors for vehicle tracking is gradually increasing (26%). Finally, 68% of the industry is focusing on Digital Procurement solutions.

In conclusion, even today when technological advances are providing solutions, companies are still faced with faster product life cycles and increased financial pressures. These two realities are often at odds, with one requiring frequent supplier sourcing and the other requiring a change in production locations to reduce lead times and meet increased demand.

The most effective way to achieve a balance in these conflicting demands is for companies to outsource some individual parts or entire supply and distribution chains, ensuring a thorough analysis of the data that will lead to the necessary improvements. In this way, even mid-sized companies can become competitive against larger ones.

Therefore, it is particularly important for a company to focus on providers that ensure flexibility in terms of transport options, as well as alternatives in the distribution part of the product, with the aim of minimizing delivery times and reducing manufacturing costs.

New technologies in the supply chain industry

Today, supply chain leaders are facing a new wave of unprecedented technological opportunities. The building blocks of Industry 4.0 – low-cost sensors and computing devices, seamless communication and powerful data analytics capabilities – are driving an explosion of innovation in the supply chain space.

IoT

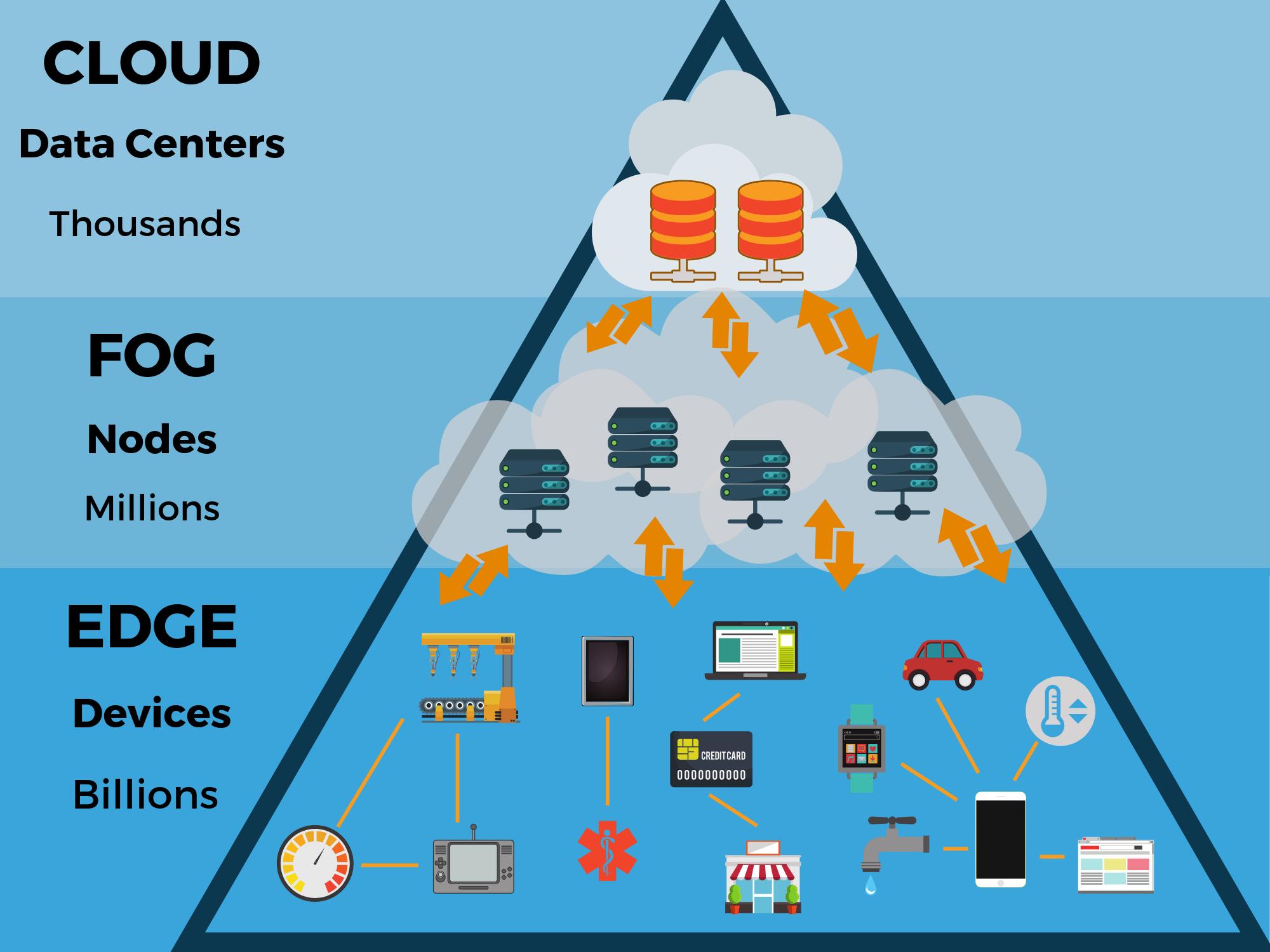

The rise of various cutting-edge technologies, where data is now processed and analysed close to the point of collection, coincides with the proliferation of devices making use of the Internet of Things (IoT). It is the technology required when there is a demand for low latency processing and automated real-time decision making.

Edge computing is now in the manufacturing industry. For example, some organizations have adopted forklifts for their warehouses. Heavy equipment vendors can use edge computing to analyze when a part needs maintenance or replacement.

Supply chain ecosystems are embracing IoT. Sensors within IoT devices measure information such as location, movement, temperature, humidity and many other factors. Some examples of IoT uses in supply chains include asset tracking, inventory management, and fleet management.

The IoT in logistics market is expected to grow at a CAGR of 13.6% by 2024, according to research.

Real-time information gathered from IoT can help customer service requirements while minimizing downtime and can enhance overall supply chain performance.

Data collected from IoT sensors on trucks can allow companies to better understand driver behavior, as well as calculate when and how much driver stops should be and the impact of traffic on estimated arrival time. With projected global e-commerce sales of $3.9 trillion in 2020 and increased demand for fast delivery, the use of IoT in logistics is likely to grow.

Automation and robotics

While industrial manufacturing – ideally exemplified by that of the United States, which includes hugely dynamic automotive and food industries – has focused on automation and robotics for decades, for the first time these technologies are becoming accessible to smaller companies.

The adoption of new solutions provides them with increased efficiency, high production speeds and reduced operating costs. However, it is important to assess whether a supply chain involving the import or export of raw materials is able to keep pace with the expected improvements.

By 2022, 938,000 robotic units are expected to operate alongside humans. Roboticisation of processes and equipment within buildings, as well as autonomous driving, is likely to have a fundamental impact on mobility and infrastructure within existing supply chains and logistics. Robotics and automation can be used to improve speed and accuracy.

In addition, day-to-day low-value tasks within supply chain operations can be improved and human errors can be minimized to reduce risk.

By working with logistics providers, who will have access to a variety of solutions for moving products across distribution networks, companies can more easily adapt to increased demands. These providers ensure access to brokerage networks, providing support to technical staff and assisting with rapid maintenance or repair procedures for automated equipment.

Cloud technologies

Web-based resource planning and applications based on these technologies can increase efficiency, especially when product manufacturing takes place in more than one geographic region. By outsourcing some of the software used and the data stored – which is constantly updated – industries can reduce several costs, particularly those related to IT departments.

The strengthening of overall supervision and the standardisation of processes, which result directly from the use of cloud technologies, can also facilitate the communication of new production processes via the internet from any production unit within and outside the country, and even with entire markets that are growing day by day.

However, industries need to assess whether these production regions have the appropriate infrastructure to transport raw materials. This requires easy access to multimodal methods of transporting, shipping, storing and distributing products.

In addition, many vendors and distributors are now positively evaluating cloud-based supply management platforms that provide real-time supply chain oversight. Such platforms require industries to constantly update the various stages of their orders, allowing the customer base to follow all the steps taken until the products are received.

By facilitating access to the various stages of the shipment, customers can accurately forecast their inventory by adjusting the inflow of products based on the demand of their own customer base.

Bulk data analysis

By taking advantage of the ability of modern technologies to capture massive volumes of data and information related to all stages of the production process, companies can benefit from their analysis, resulting in more rational strategic decision-making based on isolated and combined qualitative data.

They can also easily develop predictive models, avoiding organizational errors and unforeseen costs. Thus, their competitive advantage is dramatically enhanced as they are able to anticipate short- and long-term inventory needs with a high degree of certainty, potential problems in supply chains and the need for additional adjustments to the changing demands of their customer base.

Of course, although these kinds of data management tools could significantly enhance the competitiveness of any company, their essential success requires that supply chains and product distribution networks be able to meet the written-off needs as profitably as possible.

Digital twins

Today’s supply chain is not at the same technological level compared to a decade ago. As a direct result of the influence of technology, supply chains are complex and dynamic, and it becomes important to adopt an agile approach. With the added challenge of COVID-19, the availability of real-time data is a critical competitive advantage.

Industry 4.0 is a technology framework that focuses on digitization and analytical capabilities for real-time event tracking. This is where digital twins come in. A digital twin is essentially a virtual replica of a supply chain consisting of hundreds of assets, warehouses, logistics and inventory locations and is gaining more attention in the industry, primarily due to improvements in technical and computing capabilities.

Digital twins may seem like an interesting technology, but when combined with AI and advanced analytics, they are just the tip of the iceberg. Upgrading to intelligent, digital data analytics has been a hurdle for many supply chain businesses in recent years, but the potential value that a technology like machine learning can add is greater than ever.

For example, a big data logistics data cache can provide a transportation forecasting solution, and can estimate future supply chain needs against available capacity to proactively ensure industries proactively move freight at the right price. In the same way, industries will be able to feed IoT and sensor data from the factory into an advanced prescriptive analytics algorithm to generate recommendations for potential process improvements.

In this way, industries can become more proactive and more efficient – two things that will give them competitiveness and stability.

Sustainability enhanced by technology

Sustainability is a trend that has increasingly affected industries in recent years and the supply chain is no exception. Last mile delivery has traditionally been very time-consuming and energy inefficient, but now presents many opportunities for new and smart approaches.

To reduce negative environmental impacts, companies around the world are leveraging a plethora of new technologies, from true electric vehicles to AI-based software that calculates the route with the lowest emissions.

Deutsche Post, the world’s largest courier company, has also committed $552 million to produce light-duty electric vehicles and electric mobility units. Similar logistics technology trends are visible across the shipping sector Just recently, over 60 trade groups, including Maersk, launched an initiative that aims to use zero-carbon ships and ship fuels on the high seas by 2030.

These efforts are fundamental not only because of their immediate impact, but because they inspire the whole industry to adopt a more sustainable mindset.

Are we already in the future?

Decisions regarding capital investment have become more difficult in recent years. Companies that want to invest in new technologies are being asked to answer complex questions, such as: “How can process modernization affect our supply chain?”.

The question may seem easy, but any decision will create a series of disruptions in all areas of production, which it is advisable to anticipate. It also seems advisable to study the possibility that increased productivity will also increase the demands on product inventories, shrinking the supply base.

Undoubtedly, forecasts of the effects on the packaging sector, and in a second time the impact on the organization’s workforce, are considered absolutely necessary.

Unfortunately, there are no quick answers here. The balance will be struck by the right combination of all the proposed solutions.