MRPEasy Review: Complete Analysis of the Go-To MRP for Small Manufacturers

Uncover the core features, hidden limitations, and real-world performance to see if it’s the right fit for your business.

MREP Easy Review

MRPEasy is a powerful and affordable cloud-based manufacturing software designed for small to medium-sized businesses. It offers a comprehensive suite of tools for production planning, inventory management, CRM, and procurement, all within a user-friendly interface. While it may lack the advanced customization of larger ERP systems, its all-in-one functionality makes it an exceptional value proposition. For manufacturers with 10-200 employees seeking to streamline operations without a hefty price tag, MRPEasy is a top-tier contender that delivers on its promise of making manufacturing resource planning simple and accessible.

4.6

Pros

- Affordable pricing

- User-friendly interface

- Comprehensive features

- Seamless integrations

- Excellent support

Cons

- Limited advanced features

- Initial learning curve

- Less customization

- Advanced features cost more

Introduction

Small manufacturers face a persistent problem: managing production schedules, inventory levels, and procurement without the systems or budget that larger enterprises have.

Spreadsheets break down when your operation scales beyond a handful of products. Manual tracking leads to stockouts, production delays, and missed delivery dates.

MRPEasy positions itself as a cloud-based manufacturing software built specifically for companies with 10-200 employees. The platform promises an affordable alternative to traditional ERP systems = enterprise resource planning software that integrates all business processes in one system.

This review examines MRPEasy’s production planning, inventory management, CRM capabilities, procurement tools, and pricing structure. We’ll analyze what it does well, where it falls short, and who benefits most from choosing this platform.

Key Takeaways From Our MRPEasy Review

- Best for Small Manufacturers: MRPEasy targets companies with 10-200 employees who need standardized manufacturing processes.

- All-in-One Solution: The platform combines production planning, inventory control, sales management, and purchasing in a single interface.

- Affordability is a Major Plus: Pricing starts lower than most enterprise-level ERP systems, making it accessible to smaller operations.

- User-Friendly Design: The interface uses familiar layouts and straightforward navigation that reduces onboarding time.

- Integrates with Key Tools: Direct connections to QuickBooks, Xero, and other accounting platforms eliminate double data entry.

- Not for Complex Operations: Manufacturers with multi-site operations, highly customized workflows, or advanced production requirements may find limitations.

- Free Trial Available: Full functionality testing is available before committing to a paid subscription.

What is MRPEasy? An Overview

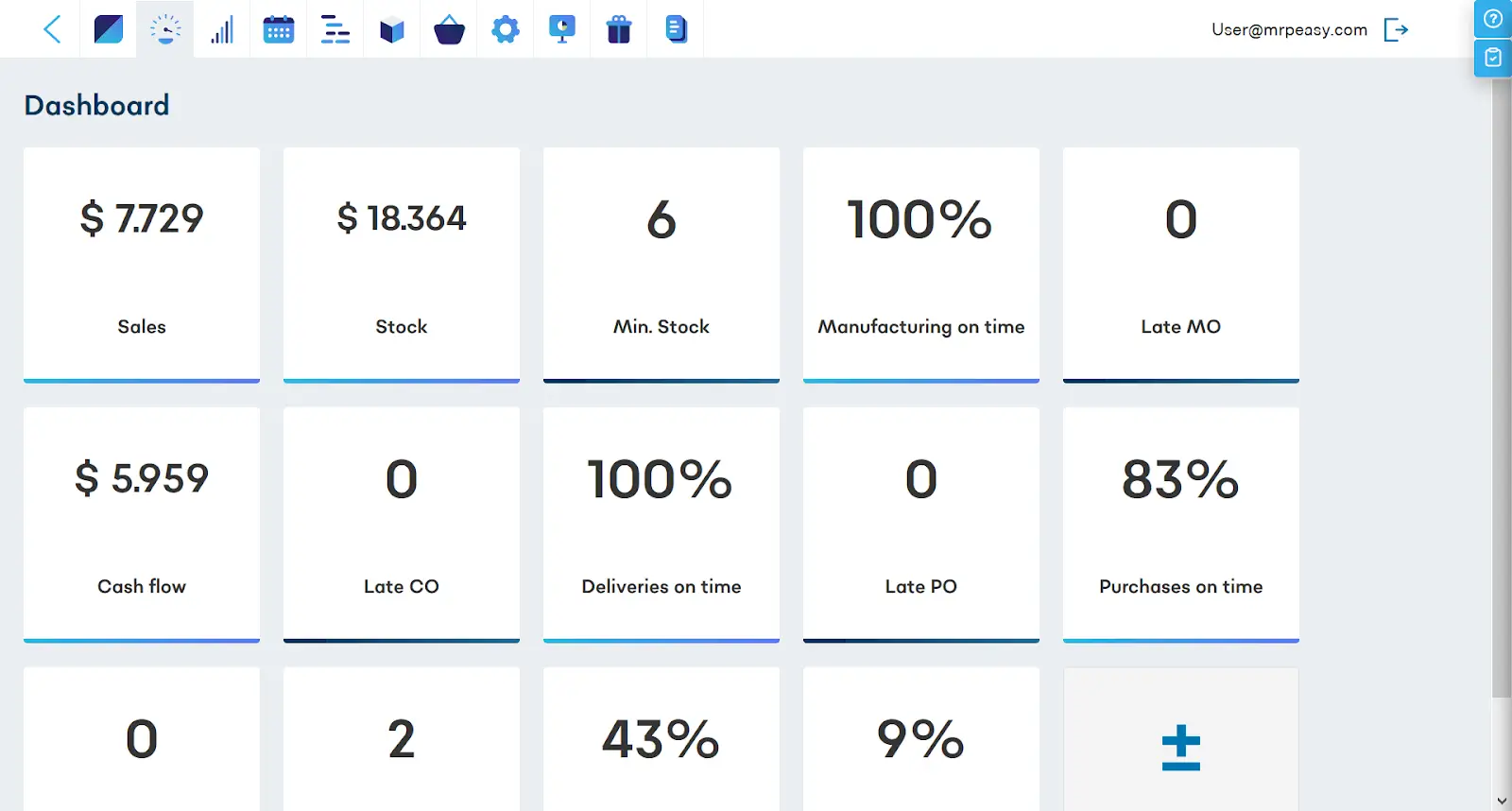

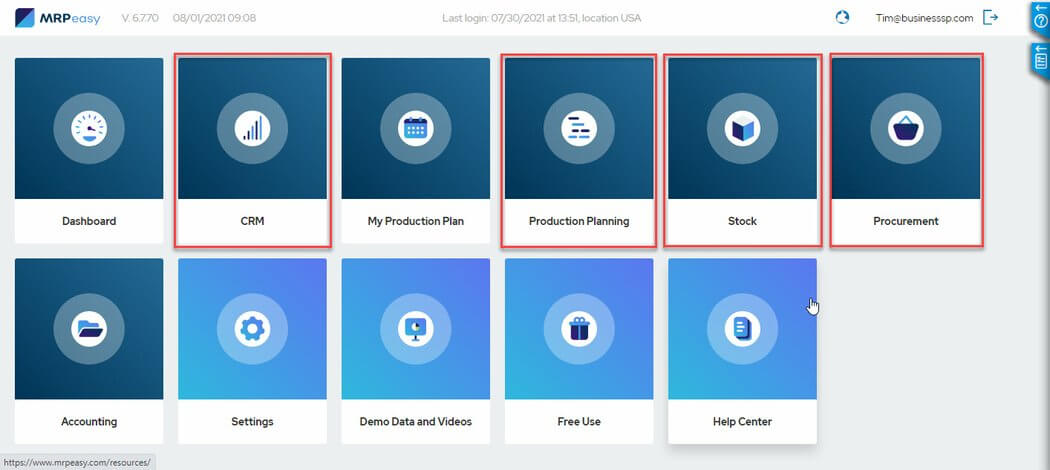

MRPEasy delivers manufacturing resource planning capabilities through a web-based platform. The software handles production scheduling, inventory tracking, order management, procurement, and basic CRM functions from a unified dashboard.

To get a quick look at the software’s interface and see its core modules in action, the official team has put together this helpful video overview

Visit MRPEasy’s Official Website →

The platform targets small to medium-sized manufacturers operating in industries like electronics assembly, machinery production, metal fabrication, and custom goods manufacturing.

Companies with 10-200 employees represent the sweet spot = operations large enough to need systematic process management but too small to justify six-figure ERP implementations.

The value proposition centers on two factors: affordability and accessibility. MRPEasy costs a fraction of traditional manufacturing software while maintaining core MRP functionality.

The cloud-based delivery model means no server infrastructure, no IT department requirements, and access from any internet-connected device.

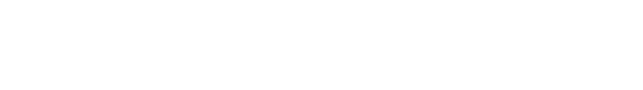

MRPEasy’s Key Features

Production Planning and Scheduling

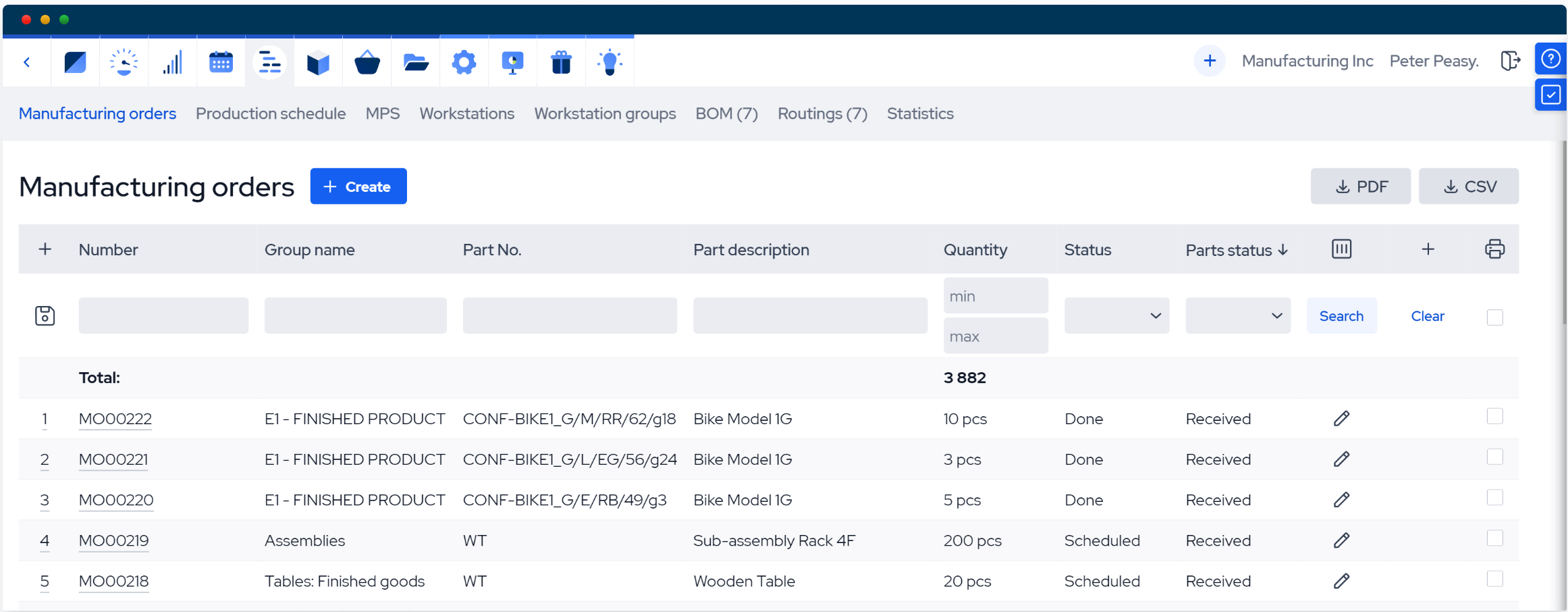

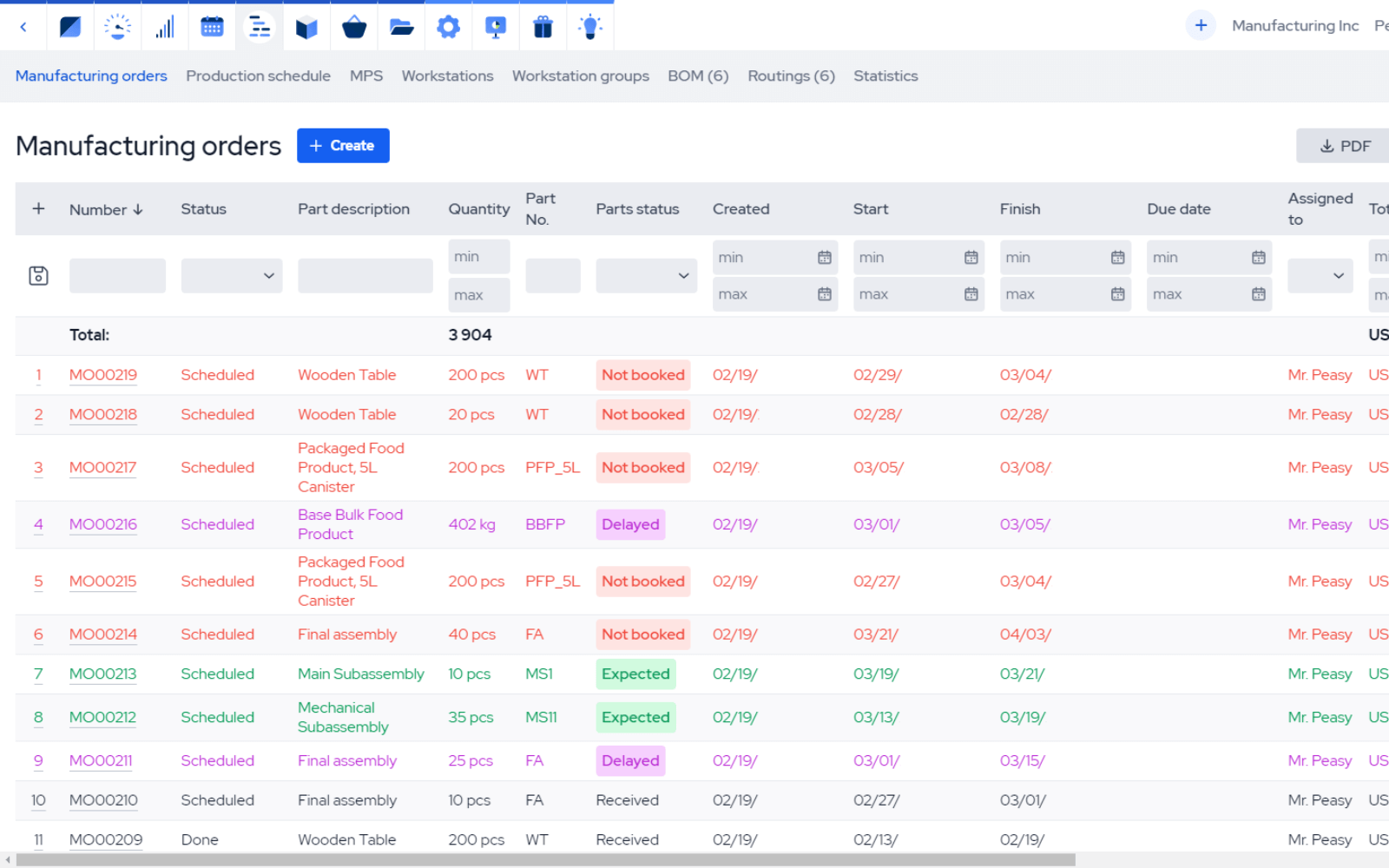

The production planning module converts sales orders into manufacturing orders based on your bill of materials. The system calculates material requirements, checks inventory availability, and generates purchase suggestions when stock runs low.

The drag-and-drop production scheduler displays work orders on a timeline where you can adjust start dates, allocate resources, and visualize capacity constraints. Gantt charts show dependencies between production stages, helping you identify bottlenecks before they cause delays.

Color-coded status indicators mark which orders are on schedule, running late, or completed. The calendar view lets you see daily, weekly, or monthly production loads across different work centers.

Inventory Management

Inventory tracking covers raw materials, work-in-progress (WIP), and finished goods across multiple warehouse locations. Real-time stock levels update automatically when you create production orders, receive shipments, or fulfill customer orders.

Serial number and batch tracking capabilities support traceability requirements. If you manufacture products requiring lot tracking for quality control or regulatory compliance, the system maintains these associations throughout the production process.

The inventory module calculates reorder points based on lead times and consumption patterns. Automatic alerts notify you when stock levels fall below minimum thresholds, preventing production stoppages from material shortages.

Stock valuation uses FIFO (first-in, first-out) or weighted average cost methods, providing accurate inventory values for financial reporting.

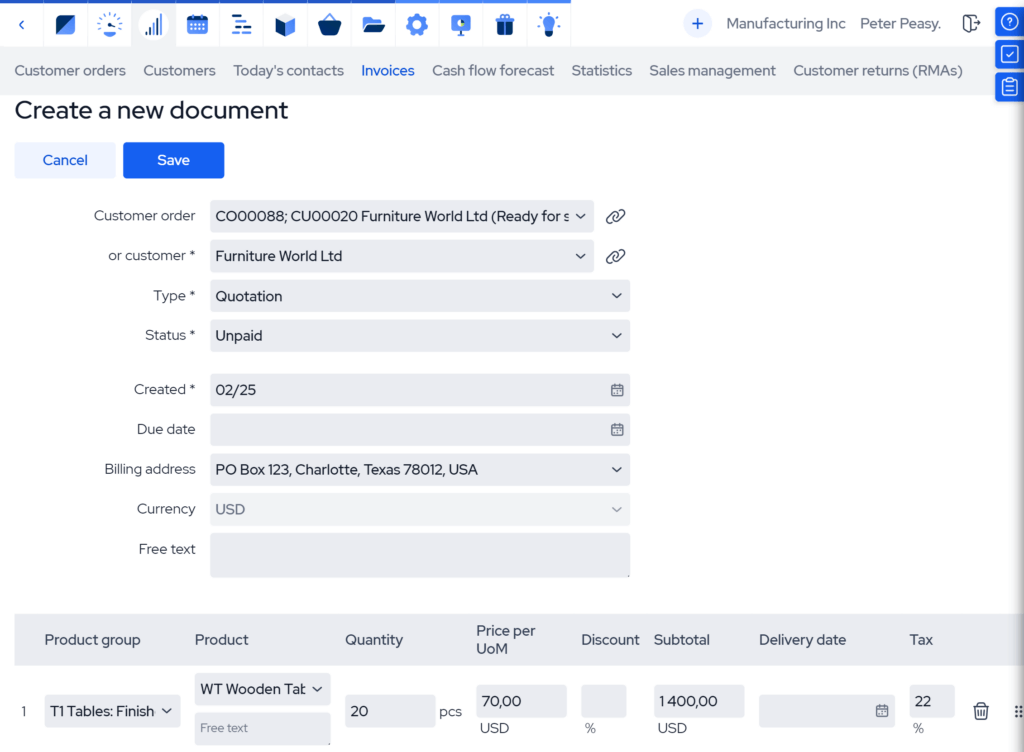

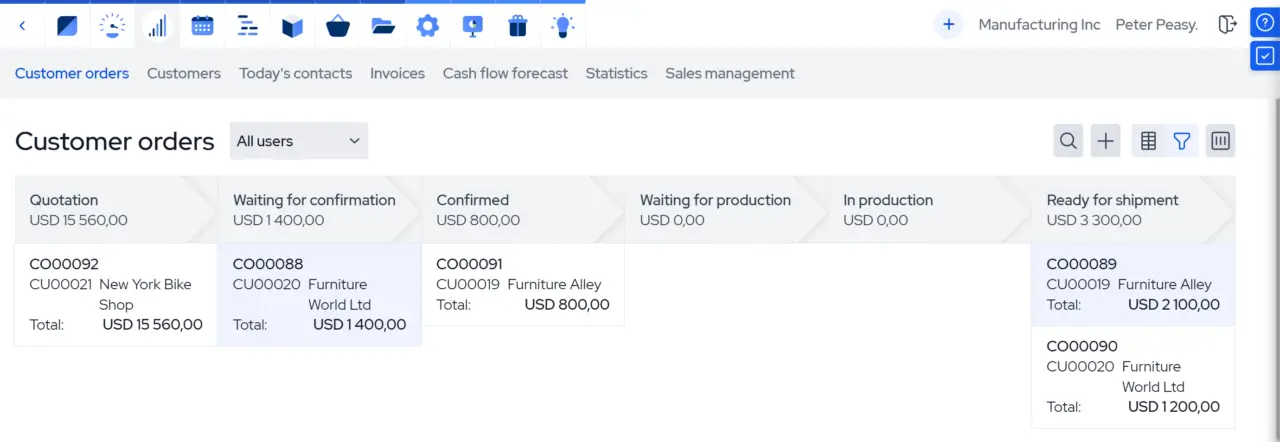

CRM and Sales Management

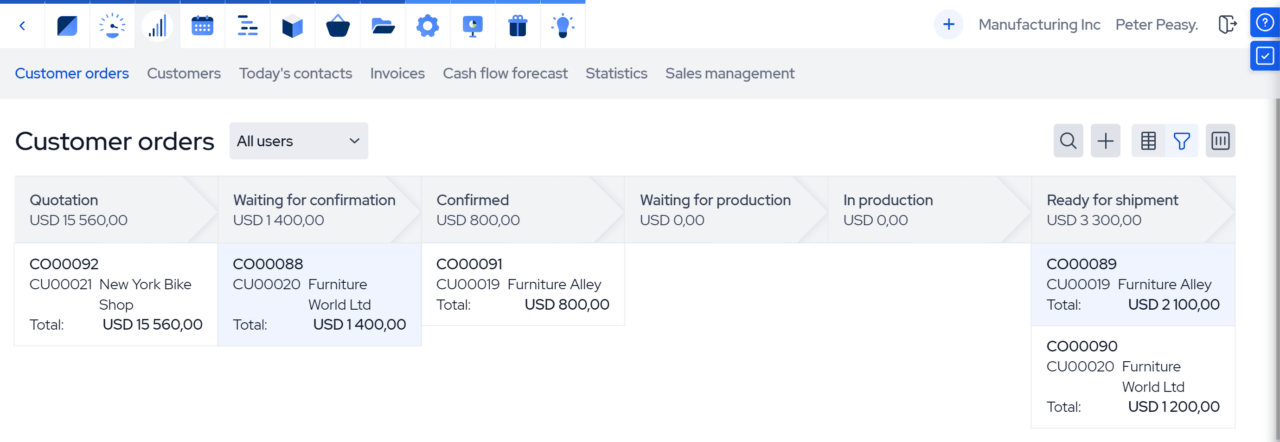

Customer relationship management functionality maintains contact information, communication history, and account details for each client. The sales pipeline tracks opportunities from initial quote through order fulfillment.

Quote generation pulls product information and pricing from your master data, creating professional proposals in minutes. Accepted quotes convert directly to sales orders without re-entering data.

The order fulfillment process links sales orders to production schedules, showing expected completion dates based on current capacity and material availability.

“But what if my customer needs a rush order?”

The system lets you prioritize specific jobs, automatically recalculating the impact on other scheduled work.

Invoicing generates directly from shipped orders, maintaining consistency between what you produced, what you shipped, and what you bill.

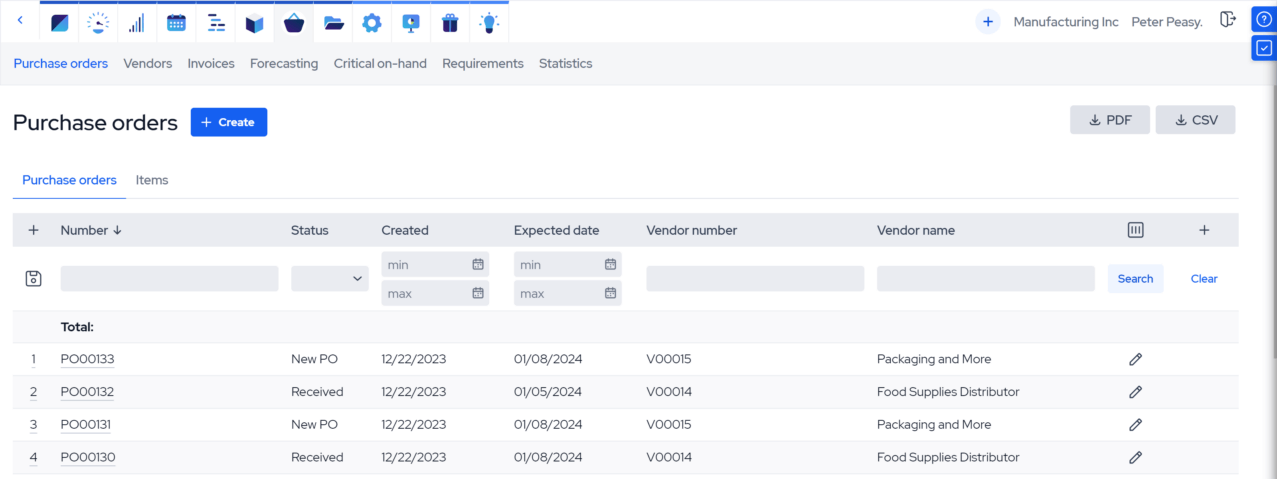

Procurement

Purchase order management streamlines vendor ordering. The system generates purchase suggestions based on production requirements, comparing needed quantities against current inventory and existing POs.

Supplier management maintains contact details, lead times, pricing agreements, and performance history for each vendor. You can compare quotes from multiple suppliers within the platform, selecting the best combination of price, delivery time, and reliability.

Receiving processes match incoming shipments against purchase orders, updating inventory levels and flagging discrepancies. The three-way match function compares POs, receiving documents, and supplier invoices to catch billing errors.

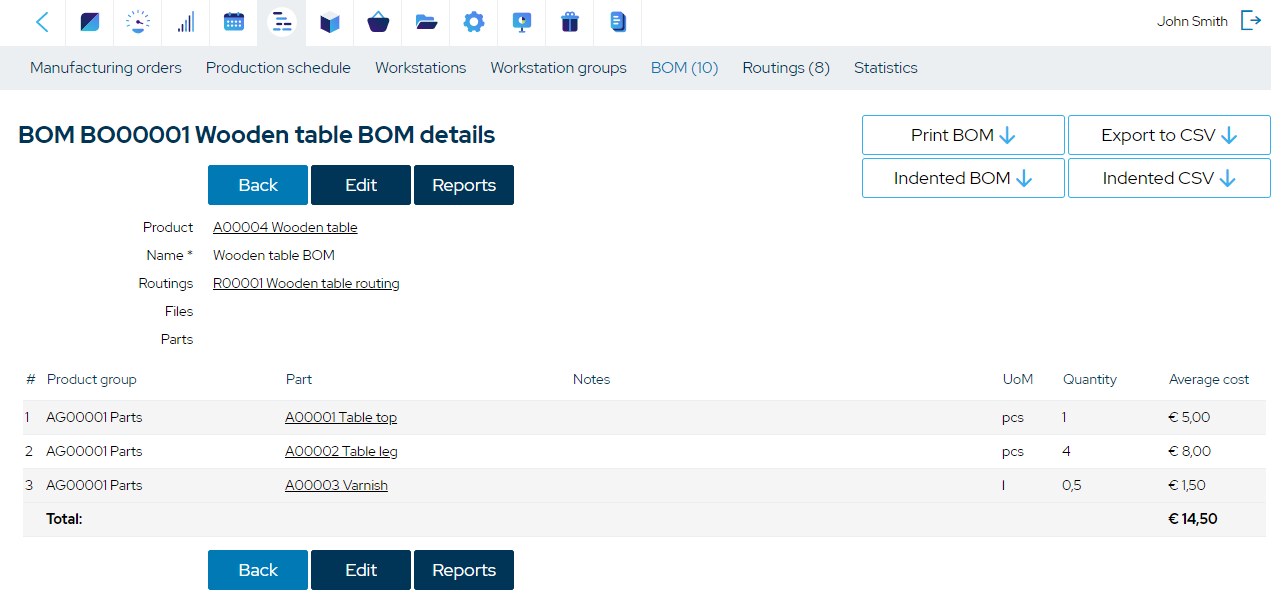

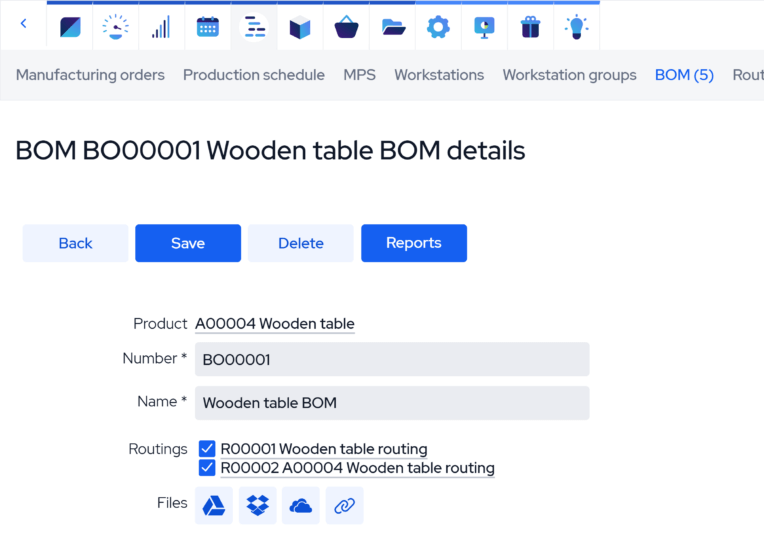

Bill of Materials (BOM)

BOM functionality defines the components, quantities, and assembly steps required for each manufactured product. Multi-level BOMs support sub-assemblies, where intermediate products become components in higher-level assemblies.

The system handles both single-level and multi-level exploding = calculating total raw material requirements across all assembly levels. This calculation drives material planning, ensuring you order components for both the final product and any sub-assemblies.

BOM versioning maintains historical records when you modify product designs, enabling traceability and allowing you to track which product versions used which component specifications.

Reporting and Analytics

Standard reports cover production efficiency, inventory valuation, order status, supplier performance, and cost analysis. The dashboard presents key performance indicators (KPIs) like on-time delivery percentage, inventory turnover, and production cycle time.

Custom report builders let you filter and arrange data according to your specific needs. Export functions output data to Excel or PDF for further analysis or distribution to stakeholders.

Stock movement reports show consumption patterns, helping identify slow-moving inventory or materials with irregular usage that complicate planning.

What I Like And What I Don’t About MRP Easy

MRPEasy at a glance

You get a simple MRP tool built for small manufacturers. It covers planning, inventory, purchasing, sales, and light CRM. It links to QuickBooks and Xero. Support and documentation are practical and fast.

🧭User-friendly interface

- Workflows mirror real production steps.

- Most users learn basics in hours, not days.

- Modules for production, inventory, purchasing, and sales share data.

💰Affordable pricing

- Lower cost than legacy ERP systems.

- Monthly subscription avoids a large upfront fee.

- Good for small shops with tight cash flow.

🧩Feature set for small businesses

- Planning, inventory, purchasing, sales, and basic CRM in one place.

- Reduces need for multiple disconnected tools.

- Delivers most core ERP functions at lower cost.

🔗Integrations

- Direct sync with QuickBooks and Xero.

- API available for custom connections. API means application programming interface.

- Saves time on manual data entry and reconciliation.

🤝Customer support

- Fast responses by email, phone, and chat.

- Documentation, setup guides, and video help available.

- Knowledge base covers common scenarios.

🧩Limited advanced functionality

- Not ideal for complex routing or strict machine hour planning.

- Multi-site transfers and advanced quality systems need stronger platforms.

- If you run engineered or project-based manufacturing, you may outgrow it.

📘Learning curve

- Staff must learn MRP terms like BOM and procurement flow.

- Initial setup requires careful data entry and validation.

- Data migration takes time and attention.

🧱Limited customization

- Config options exist, but workflow and form changes are limited.

- You may need to adapt processes to the software.

- Custom fields have limits compared to full ERP systems.

💸Pricing for advanced features

- Advanced reporting, forecasting, and some APIs sit behind higher tiers.

- Costs grow with user count.

- Small teams may see higher fees as they add features or users.

I’ll start with the areas MRP easy could improve and move down to the things I like about it.

⁉️The Cons: Where MRPEasy Could Improve

1. Limited Advanced Functionality

Manufacturers with complex routing requirements, advanced finite capacity scheduling = planning that accounts for exact machine and labor hour constraints, or detailed shop floor data collection may find gaps. The platform handles standard production workflows well but lacks the sophistication for highly engineered or project-based manufacturing.

Multi-site manufacturing with inter-plant transfers, complex demand forecasting algorithms, or advanced quality management systems require more robust platforms. Does your operation involve these scenarios? You’ll likely outgrow MRPEasy’s capabilities.

2. Potential Learning Curve

Despite being more accessible than enterprise systems, MRPEasy still requires understanding MRP concepts. Staff unfamiliar with production planning terminology, BOM structures, or procurement workflows need training beyond just learning the software interface.

The initial setup demands careful data entry. BOMs, inventory records, supplier information, and customer data must be accurate for the system to function correctly. This data migration and validation process takes time and attention to detail.

3. Limited Customization

The platform offers configuration options but not deep customization of workflows, forms, or business rules. Companies with unique processes may need to adapt their methods to fit the software rather than molding the software to match existing procedures.

Custom fields and user-defined attributes have limitations compared to fully customizable ERP platforms. “What if my industry has specific data requirements?” You’ll need to evaluate whether the standard fields accommodate your needs.

4. Pricing for Advanced Features

Entry-level plans restrict certain capabilities that growing manufacturers eventually require. Stock forecasting, advanced reporting, and API access appear in higher tiers. Very small operations might start affordably but face price increases as they need additional functionality.

The per-user pricing model means costs scale with your team size. A 50-person operation pays substantially more than a 10-person shop, even if production volume doesn’t increase proportionally.

✅ The Pros: What We Like About MRPEasy

1. User-Friendly Interface

The layout follows logical workflows that mirror actual manufacturing processes. New users typically navigate basic functions within hours rather than days. The learning curve exists but remains manageable compared to enterprise ERP platforms that require weeks of training.

Menu structures group related functions together. Production planning, inventory, purchasing, and sales occupy separate modules that share data seamlessly. You don’t need to understand the entire system to start working in one area.

2. Affordability

Pricing runs significantly lower than traditional manufacturing software packages. Small manufacturers operating on tight margins gain access to professional-grade MRP capabilities without the capital investment that typically excludes them from these tools.

The subscription model spreads costs across monthly payments instead of requiring large upfront licensing fees. This cash flow advantage matters when you’re balancing equipment purchases, inventory investment, and operational expenses.

3. Comprehensive Feature Set for Small Businesses

MRPEasy covers production planning, inventory control, purchasing, sales, and basic CRM in one platform. Small manufacturers avoid the complexity and expense of integrating separate point solutions for each function.

The feature breadth suits companies that need more than simple inventory tracking but don’t require the depth that Fortune 500 manufacturers demand. You get 80% of what a major ERP system offers at 20% of the cost.

4. Seamless Integrations

Direct connections to QuickBooks and Xero eliminate duplicate data entry between manufacturing operations and financial records. Sales orders, purchase orders, and inventory values sync automatically, keeping your books current without manual reconciliation.

API access enables custom integrations with e-commerce platforms, shipping systems, or specialized industry software. (Ed. note: API = application programming interface, the technical method that allows different software systems to communicate.)

5. Excellent Customer Support

Support responsiveness stands out in user feedback. The team addresses technical questions and setup assistance through email, phone, and live chat. Response times typically measure in hours, not days.

Documentation includes setup guides, video tutorials, and workflow examples covering common manufacturing scenarios. The knowledge base answers routine questions without requiring contact with support staff.

MRPEasy User Reviews & Common Complaints

While my analysis highlights these key strengths and potential drawbacks, the true test of any software is how it performs day-in and day-out for the people who rely on it. To give you a complete picture, I’ve dug through forums and review sites to see what real-world users are saying about their experiences with MRPEasy.

😔 User Complaints & Criticisms (What People Dislike)

- Outdated User Interface: A recurring complaint is that the user interface, while functional, looks dated. Some users feel that simple actions require too many clicks, which can slow down their workflow.

- Limited Customization: Users have pointed out that the software has restricted customization options since it’s the same for all users. This can be a drawback for businesses with highly specific or unique processes.

- Learning Curve for Beginners: While many find it user-friendly, some users with little to no prior experience with MRP software report a steep learning curve. They emphasize the need to watch tutorials and go through a proper onboarding process.

- Support Channel Limitations: A specific complaint raised is the inability to get support via email or phone, with all requests having to go through their ticketing system. A minority of users also felt that the support responses could be generic for more complex issues.

- Clunky in Certain Areas: Some users have described parts of the system as feeling “clunky” or “tedious,” particularly when it comes to tasks like data copying for custom orders or managing multi-level parts.

- Lack of Advanced Integrations: While the core integrations are praised, some users wish for more integration options with a wider variety of ERPs and other software to improve workflow efficiency. For example, limitations with Google Drive integration were mentioned.

😁 Positive User Reviews (What People Like)

- Ease of Use and Simplicity: The most common praise for MRPEasy is its user-friendly and intuitive interface. Many users, particularly those from small manufacturing companies, find it straightforward to learn and implement compared to more complex ERP systems. The workflow is often described as logical and sensible.

- Excellent Value for Money: MRPEasy is consistently highlighted as an affordable and cost-effective solution, especially for small to medium-sized businesses. Users feel they get a comprehensive set of features for the price, which is often a fraction of what larger ERP systems cost.

- Responsive and Helpful Customer Support: A significant number of users report positive experiences with MRPEasy’s customer support, describing them as quick to respond, knowledgeable, and effective in resolving issues.

- Comprehensive Features for Small Manufacturers: Users appreciate that MRPEasy covers all the essential functions they need, from production planning and inventory control to CRM and procurement, all in one integrated system. The multi-level Bill of Materials (BOM) functionality is frequently mentioned as a key strength.

- Seamless Integrations: The software’s ability to integrate with accounting software like Xero and QuickBooks, as well as e-commerce platforms like Shopify, is a major benefit for many users.

This feedback from the front lines paints a clear picture that MRPEasy is a powerful tool for its target audience, though it’s important to be aware of its limitations regarding customization and interface design.

With this balanced perspective in mind, let’s examine one of the most critical factors in any decision: the price.

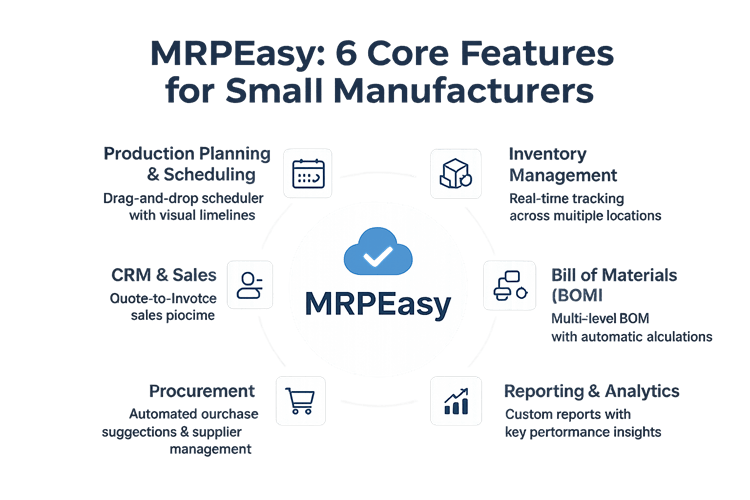

MRPEasy Pricing Plans

MRPEasy uses a tiered subscription model with per-user pricing. Costs vary based on the number of users and features required for your operation.

The platform typically offers three main pricing tiers:

- Entry-Level Plans: Cover basic production planning, inventory management, and purchase order creation. Suitable for very small manufacturers just beginning to systematize their operations. These plans generally include limited reporting capabilities and restricted access to advanced features.

- Mid-Tier Plans: Add production scheduling tools, shop floor reporting, CRM functions, and enhanced analytics. This tier fits most small manufacturers who need complete MRP functionality without enterprise-level complexity.

- Advanced Plans: Include full feature access plus API capabilities, priority support, advanced integrations, and custom reporting tools. Designed for larger operations or those requiring system integration with other business software.

Annual subscription commitments typically offer better rates than month-to-month billing. Volume pricing may reduce per-user costs for teams exceeding certain thresholds.

MRPEasy offers a free trial period (typically 15 days) with access to mid-tier or professional-level features, allowing you to test the full platform before subscribing.

Pricing ranges as of 2025: Entry plans generally start around $45-55 per user monthly, mid-tier plans run $65-75 per user monthly, and advanced plans reach $95-105 per user monthly. Custom enterprise pricing becomes available for organizations with 50+ users.

Verify current pricing directly with MRPEasy, as rates, features, and plan structures change periodically.

Here’s a clear breakdown of MRPeasy’s four pricing tiers:

| Plan | Monthly Price | Annual Price | Best For | Key Differentiator |

|---|---|---|---|---|

| Starter | €39/user | €39/user (save 1 month) | Small manufacturers starting out | Basic production and inventory essentials |

| Professional | €59/user | €59/user (save 1 month) | Growing manufacturers | Advanced features like serial numbers, subcontracting, quality control |

| Enterprise | €79/user | €79/user (save 1 month) | Established manufacturers | Multi-site operations, barcode systems, maintenance management |

| Unlimited | €125/user (min. 2 users) | €125/user (save 1 month) | Large-scale operations | API access, webhooks, unlimited limits |

Volume Pricing: Users beyond 10 cost €69 per 10 users across all plans.

MRPEasy Alternatives: How It Stacks Up Against Competitors

MRPEasy vs. Katana

Katana emphasizes visual, intuitive interfaces particularly suited to e-commerce-integrated manufacturers. The platform excels at live inventory visibility and connects smoothly with Shopify, WooCommerce, and Amazon.

Pricing for Katana runs comparable or slightly higher than MRPEasy’s mid-tier offerings. Katana’s strength lies in simplified workflows for straightforward manufacturing operations, while MRPEasy offers deeper production planning capabilities.

Target audience differs slightly: Katana appeals to product businesses selling online with direct-to-consumer models, while MRPEasy serves traditional B2B manufacturers with more complex BOMs.

MRPEasy vs. Unleashed

Unleashed focuses heavily on inventory management and stock control, with manufacturing capabilities as secondary features. The platform handles multi-location inventory particularly well and integrates with numerous e-commerce and accounting systems.

Unleashed pricing structures differ from MRPEasy’s per-user model, sometimes calculating costs based on transaction volume or inventory complexity. This pricing approach suits high-volume, low-complexity operations better than job-shop manufacturers.

Manufacturing functionality in Unleashed is less developed than MRPEasy. Companies prioritizing production scheduling and capacity planning over inventory sophistication typically prefer MRPEasy’s feature balance.

Other Competitors Worth Considering

- Fishbowl Manufacturing integrates tightly with QuickBooks and offers strong inventory control, but users report a steeper learning curve and higher upfront costs through perpetual licensing.

- Odoo Manufacturing provides open-source flexibility with extensive customization potential. Technical expertise is required for setup and maintenance, making it better suited to companies with IT resources or budget for implementation consultants.

- Cin7 targets product businesses with omnichannel sales, offering strong retail and e-commerce integration alongside manufacturing capabilities. Pricing and complexity levels sit above MRPEasy.

Comparison Table

| Feature | MRPEasy | Katana | Unleashed |

|---|---|---|---|

| Starting Price | $49/user/month | Free (up to 30 SKUs) Standard: $359-399/month | Medium: $380/month flat (3 users included) |

| Pricing Model | Per user (10+ users: +$79/10 users) | Flat rate based on sales orders & GMV | Flat rate + additional users ($109-79 per extra user) |

| Best For | Small manufacturers needing comprehensive MRP | Ecommerce businesses & light manufacturing | Wholesale, distribution & manufacturing (5-500 employees) |

| Target Company Size | 10-200 employees | Startups to growing businesses | 5-500 employees |

| Free Trial | 15+15 days (30 days total) | Free plan available (30 SKU limit) | 14 days |

| Production Planning | ✓ Advanced (MRP I & II, finite capacity) | ✓ Standard manufacturing workflows | ✓ Bill of materials, production management |

| Inventory Management | ✓ Multi-stock, lot tracking | ✓ Real-time, multi-location | ✓ Multi-warehouse, batch/serial tracking |

| Bill of Materials (BOM) | ✓ Multi-level, phantom, co-product, disassembly | ✓ Multi-level BOM | ✓ Multi-level BOM |

| Shop Floor Reporting | ✓ Internet kiosk for workers | ✓ Manufacturing app | ✓ Production reporting |

| Drag & Drop Scheduling | ✓ Gantt charts with rescheduling | ✓ Visual production timeline | ✓ Production planning |

| Quality Control | ✓ (Professional plan+) | ✓ Basic | ✓ Quality management |

| Subcontracting | ✓ With free issue materials | ✓ Limited | ✓ Available |

| Barcode Scanning | ✓ (Enterprise plan+) | ✓ All plans | ✓ All plans |

| Serial Number Tracking | ✓ (Professional plan+) | ✓ Available | ✓ All plans |

| Batch/Lot Tracking | ✓ All plans | ✓ Available | ✓ All plans |

| Multi-Location Support | ✓ Multiple stocks (Enterprise+) | ✓ 3+ locations (plan dependent) | ✓ Unlimited warehouses |

| Purchase Order Management | ✓ RFQ to delivery tracking | ✓ Built-in purchasing | ✓ Automated reordering |

| Sales Order Management | ✓ Quote to delivery | ✓ Multi-channel order tracking | ✓ B2B & B2C order management |

| CRM Built-in | ✓ All plans | Limited contact management | ✓ Optional add-on ($421/month) |

| B2B Customer Portal | ✓ (Professional plan+) | ✗ Not available | ✓ Optional ($129-199/month) |

| Accounting Integration | QuickBooks Online, Xero | Xero, QuickBooks, others | Xero, QuickBooks, Access Financials |

| Ecommerce Integration | Shopify, Magento, WooCommerce, BigCommerce | Shopify, Amazon, WooCommerce, Etsy, BigCommerce | Shopify, Amazon, WooCommerce (+$30/integration) |

| API Access | ✓ (Unlimited plan) | ✓ All paid plans | ✓ All plans (125k-500k calls/month) |

| Master Production Schedule | ✓ (Enterprise plan+) | ✗ Limited | ✓ Available |

| Maintenance Management | ✓ (Enterprise plan+) | ✗ Not available | ✗ Not available |

| Product Configurator | ✓ Matrix BOM (Professional+) | ✗ Limited | ✗ Limited |

| Multi-Currency | ✓ All plans | ✓ Available | ✓ All plans |

| Mobile App | ✓ Works on any device | ✓ Mobile-optimized | ✓ Mobile-optimized |

| Demand Forecasting | ✓ Available | ✓ Basic | ✓ Advanced Inventory Manager add-on ($100/month) |

| Business Intelligence | Microsoft Power BI integration | Built-in analytics | ✓ Optional add-on ($39/month) |

| Onboarding Fee | None | $2,000-3,000 (required for Standard+) | $449-5,549 (optional tiers) |

| Customer Support | Email, knowledge base | Live chat, email, phone | Live chat, phone, email (2hr response) |

| Notable Limitations | UI less modern than competitors | No maintenance management or advanced MPS | Higher cost for small teams |

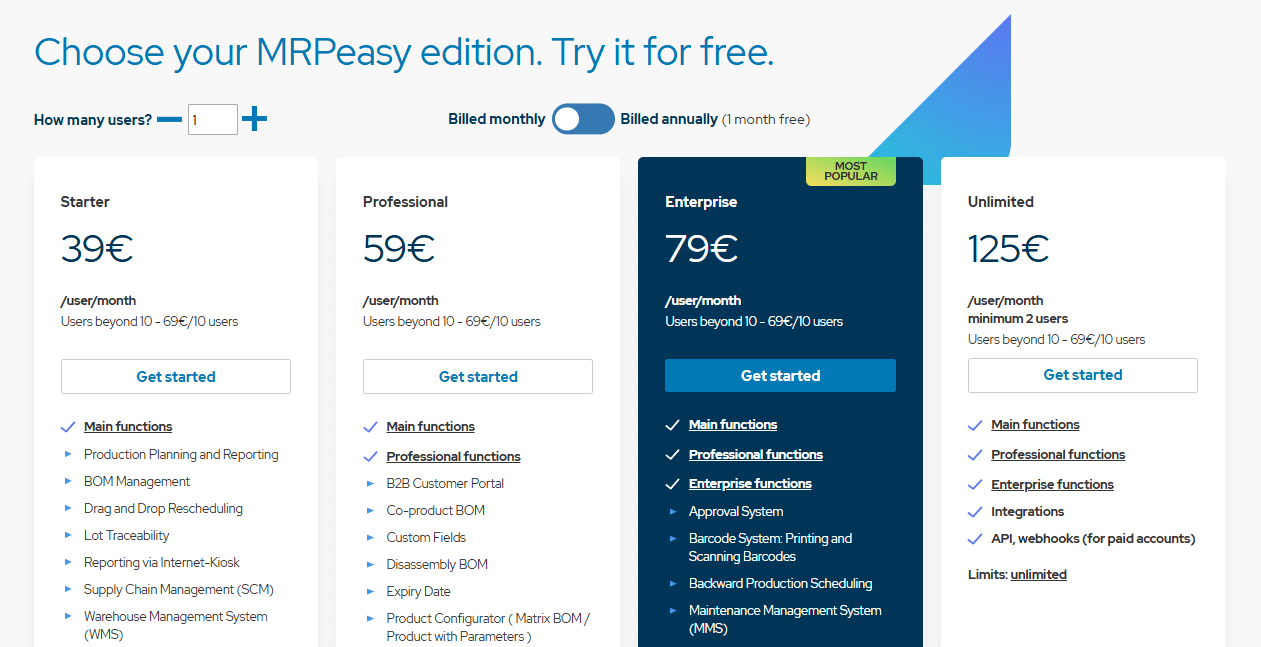

Who is MRPEasy For? (Ideal Customer Profile)

Small to Medium-Sized Manufacturers

Companies with 10-200 employees gain the most value. Operations smaller than 10 people might manage adequately with simpler inventory software, while manufacturers exceeding 200 employees often require enterprise ERP capabilities.

The platform suits organizations transitioning from spreadsheets or disconnected point solutions. You’ve reached the stage where manual coordination becomes unreliable, but you’re not ready for SAP or Oracle implementation projects.

Specific Industries

MRPEasy serves discrete manufacturing = producing distinct items like electronics or machinery rather than bulk liquids or chemicals industries effectively:

- Electronics assembly and fabrication

- Metal fabrication and machine shops

- Medical device manufacturing

- Automotive parts production

- Industrial equipment assembly

- Custom furniture and woodworking

- Food and beverage production (smaller operations)

Process manufacturers dealing with formulations, batch recipes, or continuous production may find better-suited alternatives designed for process industries.

Businesses Seeking an Affordable, All-in-One Solution

Budget-conscious manufacturers who need integrated functionality without separate systems for inventory, production, sales, and purchasing benefit most. The cost-to-capability ratio favors companies that have outgrown basic tools but can’t justify $100,000+ ERP investments.

Organizations comfortable with cloud-based software and standard workflows adapt quickest. If you need on-premises deployment or extensive process customization, alternative solutions warrant consideration.

Our Final Verdict: Is MRPEasy Worth It?

MRPEasy delivers solid MRP functionality at a price point accessible to small manufacturers. The platform handles production planning, inventory management, procurement, and sales processes competently within a user-friendly interface.

For small manufacturers operating with 10-200 employees, standard production workflows, and limited IT resources, MRPEasy represents a practical choice. The affordability, reasonable learning curve, and integrated feature set address the most common pain points these companies face.

The software falls short for operations requiring advanced manufacturing capabilities, extensive customization, or complex multi-site coordination. Highly engineered products, project-based manufacturing, or sophisticated shop floor control needs may exceed what the platform provides.

Value proposition clarity matters here: MRPEasy offers 80% of enterprise ERP functionality at 20% of the cost. If that 80% covers your requirements, you’ve found an efficient solution. If you need capabilities in the remaining 20%, factor that gap into your decision.

The free trial removes purchase risk. Test your actual workflows, import representative data, and run production scenarios that match your operation. Software selection based on real testing beats specification comparison every time.

For the right company, MRPEasy delivers manufacturing control and visibility that transforms operations from reactive firefighting to proactive planning. Is that company yours? The trial provides your answer.